RTM工藝的昨天,今天,和明天(上)

艾倫•哈珀(Alan Harper)先生供職于美國MVP有限公司,是樹脂傳遞模塑(RTM)工藝領域的著名專家。本文是關于他對RTM工藝的起源,發(fā)展和應用,以及對后來輕型樹脂傳遞模塑工藝(LRTM)的看法。

溯源RTM工藝

RTM工藝應用于復合材料行業(yè)已經(jīng)有50多年了。盡管關于RTM最初應用的時間不是十分肯定,但是曾經(jīng)有過關于英國飛機公司在50年代末開始應用RTM工藝的相關報道。據(jù)艾倫•哈珀介紹,自1973年他在英國艾爾斯伯里公司(Aylesbury)工作就開始接觸RTM工藝。當時,他們從K&C模具公司買了一臺1:1泵機,制造了第一套RTM模具。

回顧早期的模具工藝時,艾倫•哈珀用不堪回首形容。他說,利用當時的工藝在注射樹脂時只能通過模具中央的一個孔注入,直到看到模具的四個角落都流過樹脂時,人們才真正知道模具里是充滿樹脂的。因此你可以想像,經(jīng)過反復幾次生產(chǎn)后,模具的排氣口會堆著越積越厚、早已變干的、如石筍狀的樹脂,常年累月下來必然造成巨大的浪費。

雖然后來人們確實采取了更好的設計方案,比如將模腔封死,然后在其周圍鋪設導流管,直接將樹脂引流到外接到模具頂部的樹脂收集器中。但這么做仍然不能避免嚴重的浪費,雖然模具是封閉的,模腔上的排氣口仍然會釋放些許苯乙烯廢氣,不僅需要定期清洗,而且每個周期后還需要重新更換。

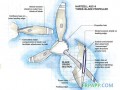

直到80年代中后期,樹脂注射工藝才開始顯現(xiàn)出一些自動化的跡象。當時工藝的主要進展在于,操作人員不必攜帶著注射閥爬到模具上方,將注射頭插入模具的注入口中,同時在整個注射過程中緊緊抓住注射頭。待注射完成后將注射閥拔出,然后再迅速用塞子堵上模具的注入口,以防止樹脂倒流。當談到早期的RTM工藝,人們可能會笑,但是在那個年代,這樣的工藝確實存在了許多年。

圖1:在早期的RTM工藝過程中,操作人員需要手持注射閥,將其插入模具的注入口中。

而后,自動注射閥(AutoSprue)的發(fā)明又將RTM自動化的程度提高了一些,因為它代替人工將其插入模具的步驟。但是,對模腔中的樹脂仍然使用的是舊方法進行管理。

隨著RTM工藝的進一步發(fā)展,出現(xiàn)了更為先進的輕型樹脂傳遞模塑工藝—LRTM,該工藝的首次應用是于1970年在德國。到1996年,法國Alwo公司主管讓•雅克(Jean Jacques Sick)將LRTM工藝介紹給美國MVP公司閉模工藝專家查爾斯•圖爾(Charles Tur)和法國國家成人職業(yè)協(xié)會(AFPA)復合材料講師讓•保羅(Jean Paul Galichet)。

當時,查爾斯•圖爾還有另一個身份是比利時原料供應商Socomer的技術支持顧問,他一直致力于推進這項新工藝的進展,并對他們的客戶進行相關培訓。AFPA講師讓•保羅則將這門新工藝作為技術培訓教案教授給學生。

與此同時,肖馬拉復合材料公司(Chomarat Composites)也將混合氈—Rovicore推向市場,由于很好地迎合了低壓注塑樹脂滲透工藝的需求,一經(jīng)上市就廣受好評。到1998年,肖馬拉公司開始奔走于世界各地,實地向客戶展示如何運用LRTM新技術和模具制造Rovicore混合氈。

同年,查爾斯•圖爾將LRTM介紹給Plastech公司(當時是艾倫•哈珀的公司),一經(jīng)采納當即看到了這項新工藝的真正優(yōu)勢和潛力。Plastech公司趁熱打鐵開發(fā)了一套RTM設備和模具配件(如密封件等),為其客戶提供一個完整的LRTM工裝包。Plastech還將LRTM技術作為在其全球RTM的培訓課程的內(nèi)容之一。

因此,LRTM工藝在90年代一經(jīng)推出,立即給市場帶來了一個更清潔的樹脂注射系統(tǒng)。除了具有明顯的成本和輕量優(yōu)勢,該工藝還降低接觸液體樹脂混合物的機會。LRTM的出現(xiàn)代表著整個閉模工藝發(fā)展的頂峰期,如今的用戶在操作上已經(jīng)變得越來越嫻熟,能按需精準的建造模具。LRTM跟RTM很像,也是采取上下兩片閉合模具,但是比傳統(tǒng)RTM工藝的生產(chǎn)工作環(huán)境更清潔,而且浪費率更低。與RTM相反,LRTM工藝是讓樹脂先流經(jīng)模具周邊,最后多余的樹脂從位于中央的出口流出。所有這些過程都在真空密封環(huán)境中進行,因此揮發(fā)性有機化合物排放量幾乎為零。

英文原文:

RTM – past, present and future

Alan Harper

Alan Harper, closed mould specialist at MVP Ltd, is a well-know expert in resin transfer moulding (RTM) technology. Reinforced Plastics asked him for his views on the future of this processing technique.

Reinforced Plastics: When was the RTM process first used?

Alan Harper: To my knowledge RTM has been used for over 50 years. I became involved in RTM when working in Aylesbury, Bucks, UK, in 1973. We bought a 1:1 pump machine from K&C Mouldings and made our first RTM mould. Looking back, our mould technology was horrendous as when the resin was injected through a central mould hole, we only really knew it was full when resin poured from all four corners. Consequently you can imagine that after a few days of production we had huge wasteful stalagmites of harden resin on the floor growing daily towards the mould outlets. We did get better and designed the seals to run all around the mould cavity and installed pipes to direct the exiting resin into open cups balanced on the mould top. However, it was really wasteful, and although closed mould, the open vents still gave off styrene fumes and needed cleaning and renewing for each cycle.

I cannot be sure of the original use of RTM but have read that a UK aircraft company started to apply a form of RTM in the late '50s.

Reinforced Plastics: How did the process develop in terms of automation and control?

Alan Harper: It was not until the late mid '80s that a degree of automation in the actual injection of the resin started to appear. The main advance was to eliminate the need for the operator to climb onto the mould armed with an injection machine head, thrust it into the mould injection sprue port, and forcefully hold it down throughout the injection phase. After removing the nozzle a plug was quickly inserted manually to prevent resin back flowing. We laugh at this now but it really was like that for many years.

An AutoSprue was developed whereby the machine could simply be plugged into the mould injection port allowing hands free injection and flushing. However exiting resin still had to be managed by the old method.

Reinforced Plastics: When did Light RTM (LRTM) first appear?

Alan Harper: Light RTM technology was first developed in Germany in 1970. In 1996, Jean Jacques Sick, director of Alwo, France, introduced the Light RTM process to Charles Tur (currently closed mould specialist, MVP USA) and Jean Paul Galichet (composite teacher at AFPA, the French national association for adult vocational) through Alain Floret of Chomarat.

Charles, who was working as a technical support for Socomer, a raw material supplier in Belgium, continued to develop the process and conducted training to help their customer base to make their own moulds. Jean Paul Galichet, teacher at the AFPA (French government training centre) included the technology in their composite training programmes.

At the same time, Les Fils d'August Chomarat (Chomarat Composites) brought to the market their well known combination mat, Rovicore, which was ideally suited to the process by providing excellent permeability for the low pressure resin injection.

In 1998, after several demonstration days with AFPA Laval and Socomer, Chomarat engaged Charles Tur to use his experience with the process, to travel the globe to demonstrate Rovicore to their clients using the new LRTM techniques and moulds.

The same year, Charles Tur introduced the process to Plastech, the company I then owned, and we immediately saw the real advantages and potential of Light RTM. Plastech developed an RTM Machine and mould accessories, seals, etc. to provide a Light RTM package for their customer base. Plastech also combined Light RTM Technology to their existing worldwide RTM training courses.

Thus the introduction of the Light RTM process, in the '90s, immediately brought about a much cleaner resin injection system. Apart from its advantage of utilising much lower cost lightweight moulds, the process eliminated any need for the operator to be exposed to liquid resin mixes. This led to an enormous upsurge in a truly closed mould application in our industry which continues today as more users become proficient with the prerequisite to build their own accurate closed moulds. We are not speaking here about film infusion, which could be called closed mould, as it has only one engineered moulded surface and usually requires a new 'B' surface film tool for each production cycle.

Light RTM, like the original RTM method, produces two engineered moulded surfaces and far less wastage with considerably cleaner working environment over traditional RTM. Light RTM delivers the resin around the mould periphery and exits into a central catchpot. All this is under a modest vacuum level providing zero exposure to VOCs.

魯ICP備2021047099號

魯ICP備2021047099號